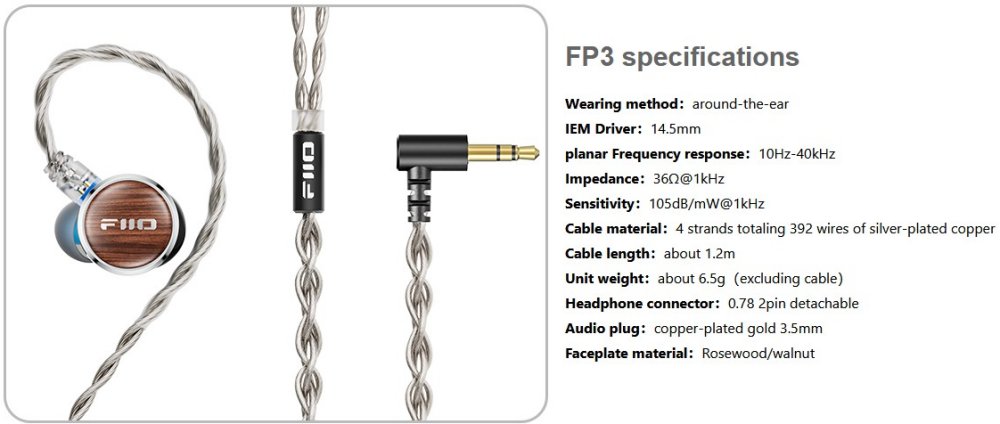

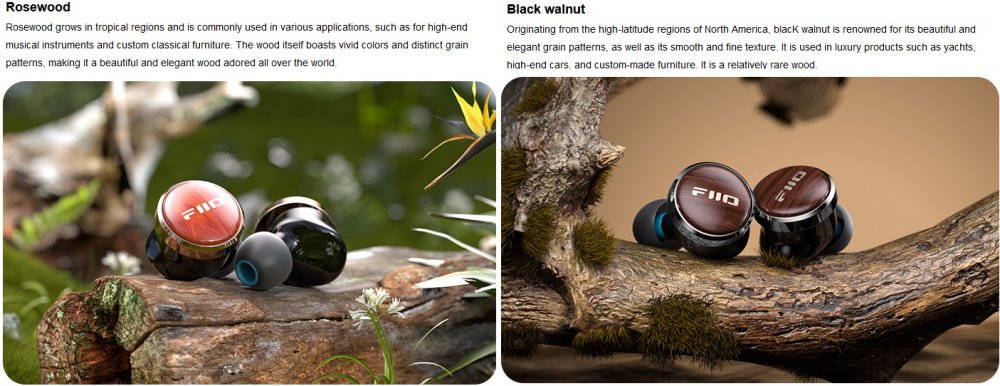

After years of meticulous work, FIIO has created the FIIO FP3, featuring a second-generation, entirely self-developed 14.5mm planar driver. The diaphragm thickness is merely 1μm, the thinnest among its peers, achieved in part thanks to FIIO’s new dual-coating patented technology. The driver was designed to deliver excellent sound quality and impressive dynamics. The FP3’s appearance draws inspiration from a “mini wooden bowl.” Prominent on the FP3 is a pure wood faceplate, with options for rosewood or black walnut finishes. Each earbud weighs only about 6.5g and features ergonomic enhancements for comfortable and worry-free wear.

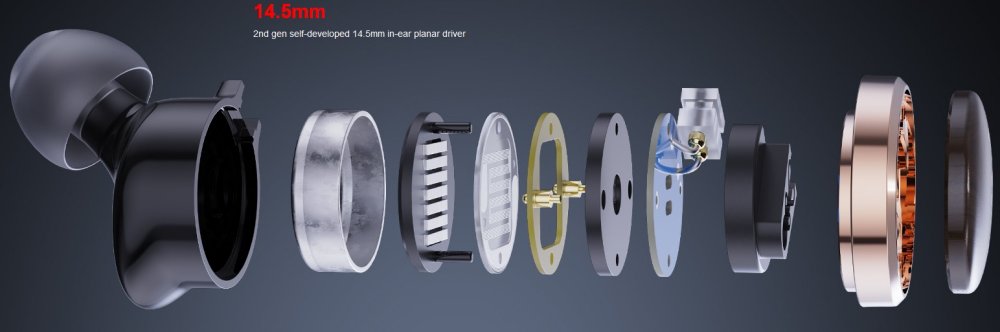

2nd gen self-developed 14.5mm in-ear planar driver

The FP3 is equipped with FIIO’s second-generation, self-developed 14.5mm in-ear planar driver. The planar driver has been designed from the ground up by FIIO, from the diaphragm to the patented dual-coating, to the conductive trace width, to the fine-tuning of the magnetic circuit, and even the standardized bracket fixings. Compared to typical off-the-shelf drivers, the self-developed driver can be completely customized to build and fit around it a sophisticated acoustic system, allowing the driver to achieve significant breakthroughs in sound quality.

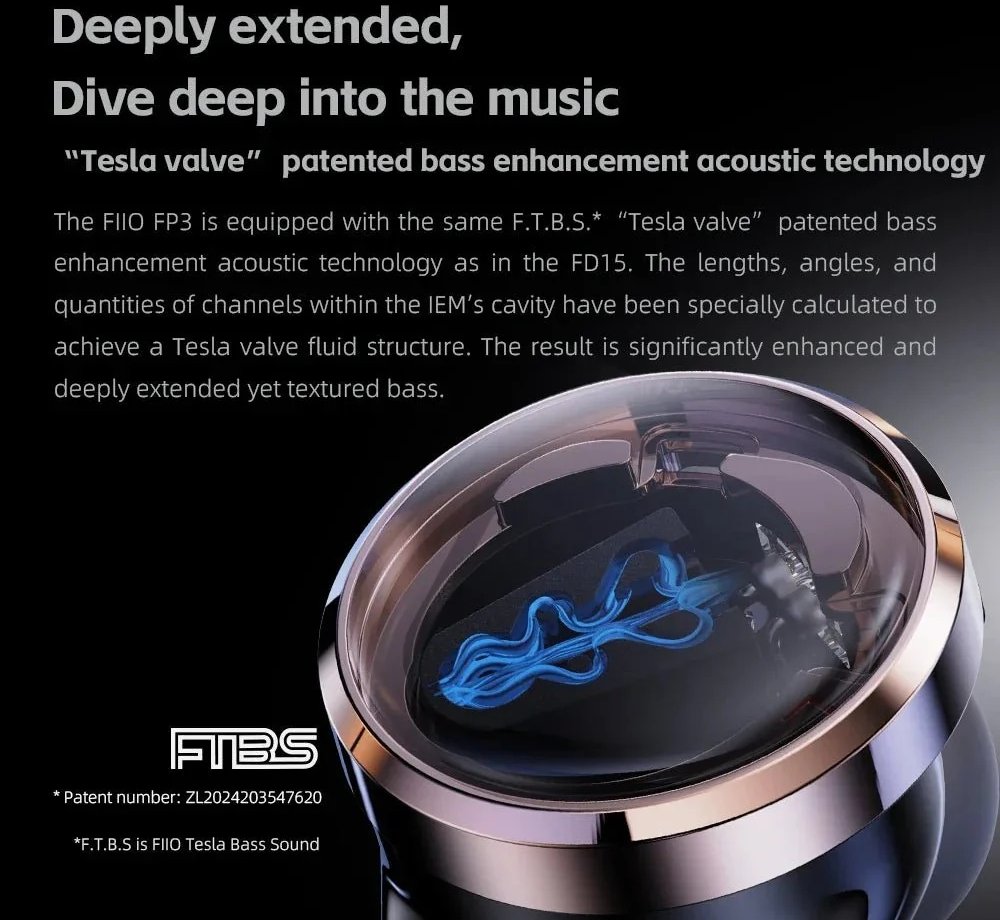

Thanks to this intensive research and development, the FIIO FP3 features a large, almost limitless soundstage rarely found among its peers. It also effortlessly produces deep bass and detailed treble up to 40kHz, allowing you to dive into the music fully.

A true standout - 1μm ultra-thin diaphragm

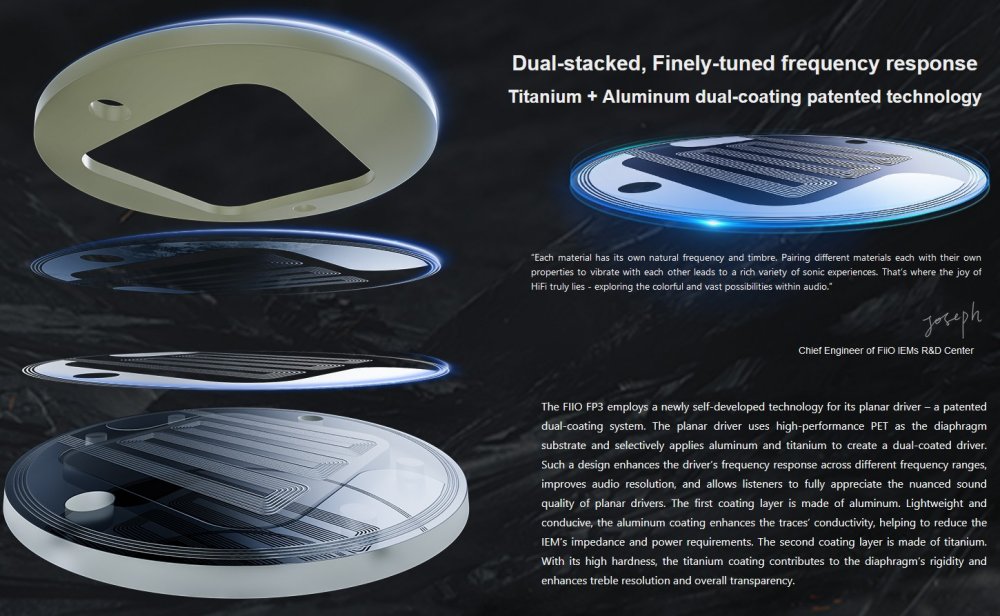

Engineers have constantly strived to achieve thinner and lighter diaphragms for planar drivers. After two years of independent research and development, we have created a class-leading 1μm ultra-thin diaphragm, using high-performance PET as the substrate. The difference between even a 2μm and a 1μm diaphragm thickness results in noticeable performance differences when the diaphragm is vibrating at high speeds, which ultimately affects sound quality. The FP3’s 1μm ultra-thin diaphragm is exceptionally lightweight, allowing it to respond with lightning-quick speed. It faithfully reproduces even subtle sounds in the ultra-high frequency range, as well as providing exceptional dynamic range.

Advanced technology for advanced sound - 28 nm-grade process technology

In order to achieve high sound quality with the intricate second-generation self-developed planar driver, the FP3’s driver needs to be manufactured with precision at the manometer level. Traditional diaphragm coating processes are not precise enough.

To have its driver diaphragm manufactured with sufficiently high quality, the FIIO FP3’s driver is made using a 28 nm-grade process. This technique, inspired by coating technology used within the semiconductor industry, completely isolates the conductive trace material from the surrounding air. The trace material exists in a vacuum state at a pressure of 6.6 × 10⁻³ pascals, and the temperature is raised to 120°C. The trace material is transformed into ionized particles, which then accumulate on an ultra-thin 1μm film through charge attraction principles. This process creates the desired coating thickness for optimal acoustics and significantly enhances the durability and lifespan of the traces.

Additionally, the FP3 goes beyond industry standards by applying this complex and rigorous process twice to each diaphragm, resulting in a dual-coated membrane design that delivers exceptional sound quality.

Hair-like thinness - 0.055mm ultra-fine conductive traces

The conductive traces on the FIIO FP3’s planar driver were designed according to the force principle acting on a coil in a magnetic field, F = BIL*. FIIO leveraged a high-precision 28 nm-grade manufacturing process, allowing the conductive traces on the FP3’s driver to be a width of merely 0.055mm – as thin as a strand of hair. By making each individual trace narrower, FIIO can pack more traces more densely within the effective magnetic field. The total length of the FP3’s traces is 486.5 mm, significantly enhancing the driving force experienced by the diaphragm while simultaneously improving headphone sensitivity.

*Under constant magnetic field and input current, longer coils within the magnetic field experience greater force, leading to larger diaphragm oscillations and higher sensitivity.

Balanced force - Dual-sided 14 N52 neodymium magnets

In order to achieve a comfortable and lightweight design, the development team decided to place 7 N52 high-performance neodymium magnets on both sides of the FP3’s driver. These magnets are arranged in a 7x2 pattern, totalling 14 in all. The balanced placement of these magnets allows the dual-coated traces to be distributed evenly within the magnetic field. This completes a matrix-style magnetic circuit system, ensuring that the diaphragm experiences balanced forces on both sides. As a result, the diaphragm does not move in irregular ways, which reduces distortion and achieves high-fidelity sound.

Designed for comfort

To balance both lightness and comfort, the FIIO FP3 features a front shell made from high-precision 3D printing. This allows the shell to be flexibly shaped to a design comfortable for ears. This front shell is manually polished and undergoes UV coating, leading to a luxurious texture.

The FIIO FP3 features a specific support structure in the concave auricle area, which improves stability during wear. The design reduces the contact area with the human ear and this minimizes pressure on the earlobe. Combined with the lightweight net weight of the headphones, the result is a comfortable listening experience.

Lightweight – only 6.5g per unit

The FIIO FP3 is a planar IEM that was designed to be light for a comfortable, effortless listening experience. To achieve this, the acoustic team has meticulously optimized the product’s weight while ensuring sound quality was not compromised. The weight of each FP3 unit is approximately 6.5 grams, making it fatigue-free for extended listening sessions and ahead of its peers in comfort.

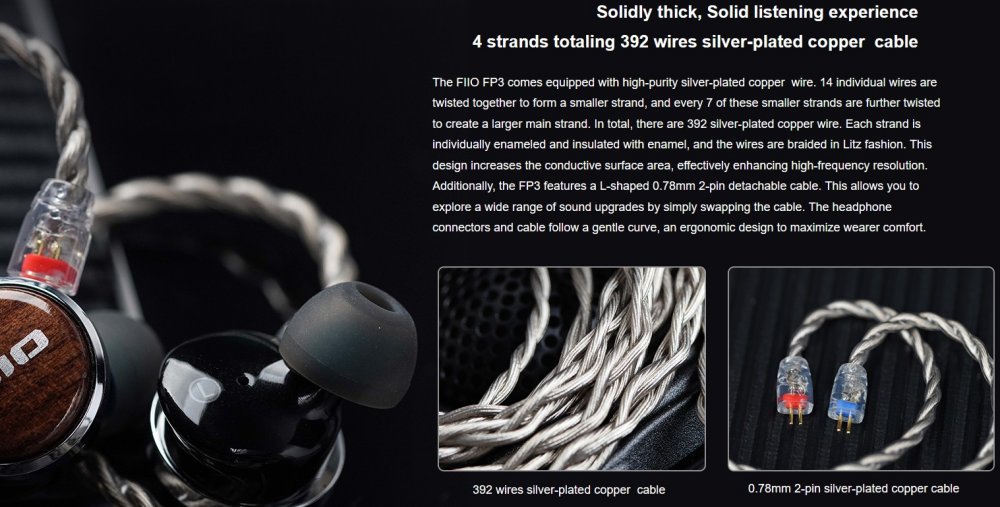

Solid listening experience - 4 strands totalling 392 wires of silver-plated copper cable

The FIIO FP3 comes equipped with high-purity silver-plated copper wire. 14 individual wires are twisted together to form a smaller strand, and every 7 of these smaller strands are further twisted to create a larger main strand. In total, there are 392 silver-plated copper wires. Each strand is individually enamelled and insulated with enamel, and the wires are braided in Litz fashion. This design increases the conductive surface area, effectively enhancing high-frequency resolution. Additionally, the FP3 features a L-shaped 0.78mm 2-pin detachable cable. This allows you to explore a wide range of sound upgrades by simply swapping the cable. The headphone connectors and cable follow a gentle curve, an ergonomic design to maximize wearer comfort.

Hi-Res Audio certified

The FIIO FP3 has been certified by the Japan Audio Society (JAS) and the Consumer Electronics Association (CEA) to be Hi-Res Audio capable, a testament to the IEM’s ability to faithfully reproduce sound.